Ant-i2 is a next-generation selective wave soldering machine with the following features:

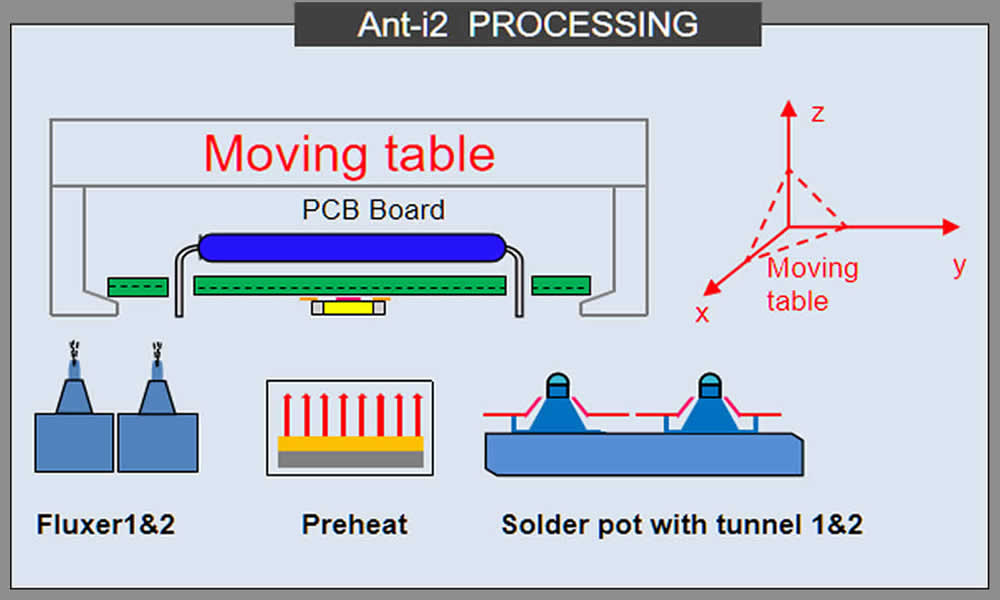

● One drop jet fluxer

● Bottom IR preheating, optional with top preheating zone

● One solder pot with two individual wave tunnels

● PCB moves in X/Y while solder pot/fluxer moves in Z

● Single soldering nozzle handles max 350 x 215 mm

● Two nozzle could soldering max 350mm x 215mm parallel

● Windows 10 operating system

● Three-axis full servo drive with ball screw movement

● Standard equipped with wave height calibration

● Real-time soldering process monitor

| Ant-i2 Offline Selective Soldering Machine Specifications | |

|---|---|

| Item | Ant-i2 |

| General | |

| Operating power/Max power | 7KW/13KW |

| PCB dimension | 50x50---350x450mm (when use only one solder nozzle), 50x50---350x215mm (when use two wave nozzles parallely) |

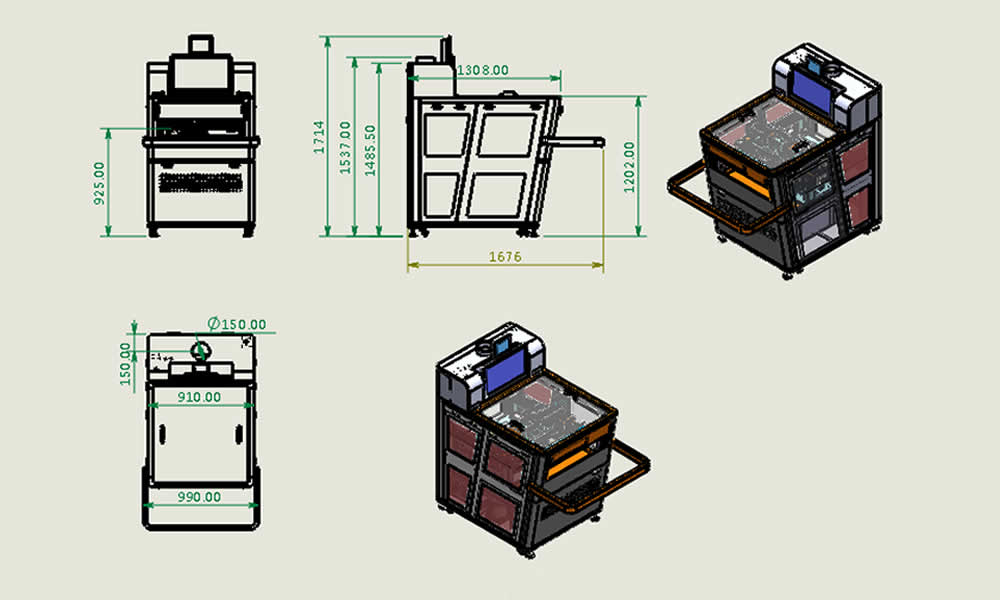

| Machine dimension | W1260mm x D1640mm X H1895mm |

| Net weight | 550KG |

| Power supply | 3PH 380V 50HZ MAX 34A Equip 40A contactor in factory |

| Air supply | 3-5 bars |

| Exhausting required | 200M3/h |

| Controlling System | |

| Industrial PC | Yes |

| Typical Program Time | 10 Minutes |

| Program method | Draw path in scanned picture of board |

| Controlling system | PC |

| PCB Robotic Platform | |

| Axes of Motion | X, Y, Z |

| Motion Control | Servo motors for X,Y,Z |

| Position Accuracy | + / - 0.05mm |

| Flux Management | |

| Flux Nozzle type | drop jet nozzle made in Germany |

| Flux nozzle number | 2 sets |

| Flux Capacity | 1L |

| Flux Tank | Constant pressure tank |

| Preheat | |

| IR heater | 5kw |

| Solder Management | |

| Standard Solder Stations | 1 |

| Solder Pot Capacity | 35 kgs |

| Solder Temperature Control | PID |

| Heat-Up Time | About 50mins |

| Solder Pot heater | 380 ℃ |

| Solder Pot heater | 2.4kw |

| Solder level alarm | standard |

| Wave tunnel | two individually |

| Wave control | servo motor, mechanical pump |

| Solder Nozzles | |

| Mini Wave Nozzles | Dia 4, 6,8,10,12mm |

| Customized nozzle | Available |

| Nozzle Material | Proprietary Alloy |

| (N2) Inertion Management | |

| N2 heater | Standard Equipped |

| N2 Temp PID Control Range | 0 - 350℃ |

| N2 Consumption per Nozzle | 1.5m3/H Total need: 3m3/H (Recommend to connect with Selmate-4 N2 generator) |

| Required N2 Purity | >99.99% |