Highest flexibility, compact in-line

machine with the following features:

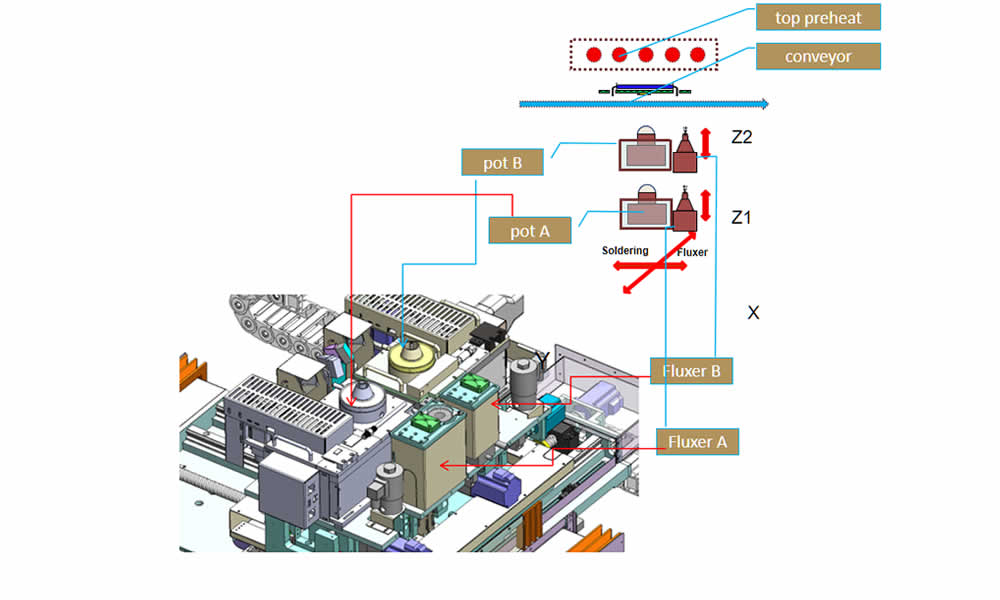

1 drop jet fluxer as standard, with an optional extra

Bottom IR preheating & top preheating zone

2 solder pots in individual Z-axis

One section conveyor

Fixed PCB conveyor with moving solder pot/fluxer

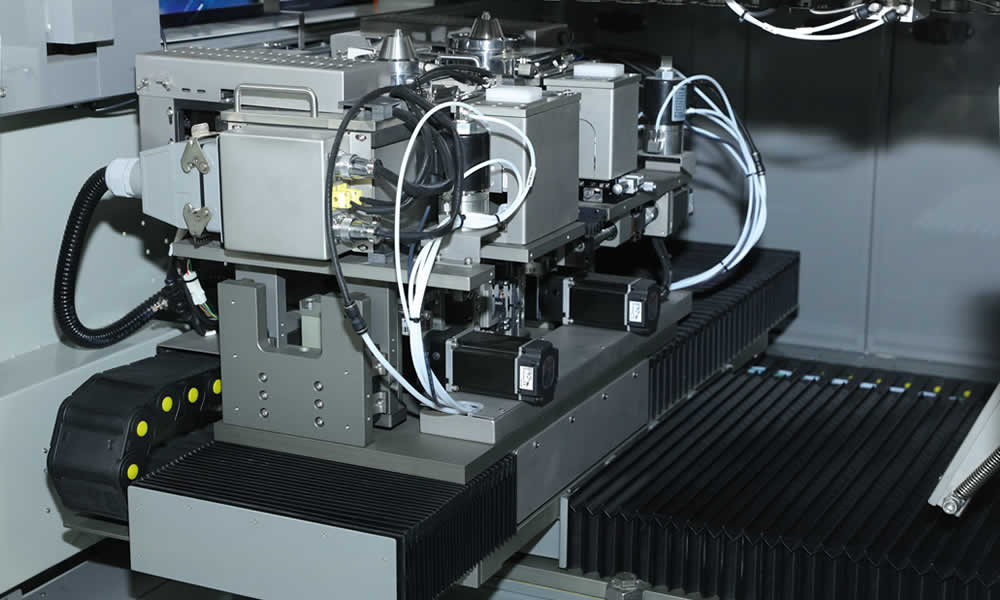

4-axis full servo drive with ball screw movement

Solder pot and fluxer share XY motion table

All-in-one flux, preheating & soldering

Windows 10 system

Standard equipped with wave height calibration

Real-time soldering process monitor

| FLEX-i2 Specifications | |

|---|---|

| Item | FLEX-i2 |

| General | |

| Operating power/Max power | 6KW/16KW |

| PCB dimension | Min50x50---Max PCB W457.2 x L508mm (18" x 20") (Two nozzle solder individually) Max PCB W508 x L508mm (20" x 20") (Two nozzle solder parallel) |

| Machine dimension | 1420(L)*1725(W)*1700(H) |

| Net weight | 900KG |

| Power supply | 3PH 380V 50HZ |

| Air supply | 3-5 bars |

| Exhausting required | 800M3/h |

| PC | Yes |

| Typical Program Time | 10 Minutes |

| PCB Robotic Platform | |

| Flux Nozzle Type | drop jet fluxer made in Germany |

| Flux Nozzle Quantity | Standard equip 1 set, optional to equip another set |

| Flux Tank Capacity | 1L |

| Flux Tank Quantity | Standard equip 1 set, optional to equip another set (when use two different flux) |

| Preheat | |

| Preheating method | Top IR preheat,option with bottom preheat |

| Solder Management | |

| Solder pot type | Standard equipped with mechanical pump, optional with electromagnetic pump (made in Germany) |

| Standard Solder Stations | 2 |

| Solder Pot Capacity | 15 kgs |

| Solder Temperature Control | PID |

| Heat-Up Time | About 40mins |

| Max Temperature | 350 ℃ |

| Mini Wave Nozzles | 3 to 12mm |

| Customized nozzle | Available |

| Axes of Motion | X, Y, Z1, Z2 |

| Position Accuracy | + / - 0.05mm |

| (N2) Inertion Management | |

| 1.5m3/H Total need | 4m3/H |

| 3m3/H (Recommend to connect with Selmate-4 N2 generator) | >99.99% |