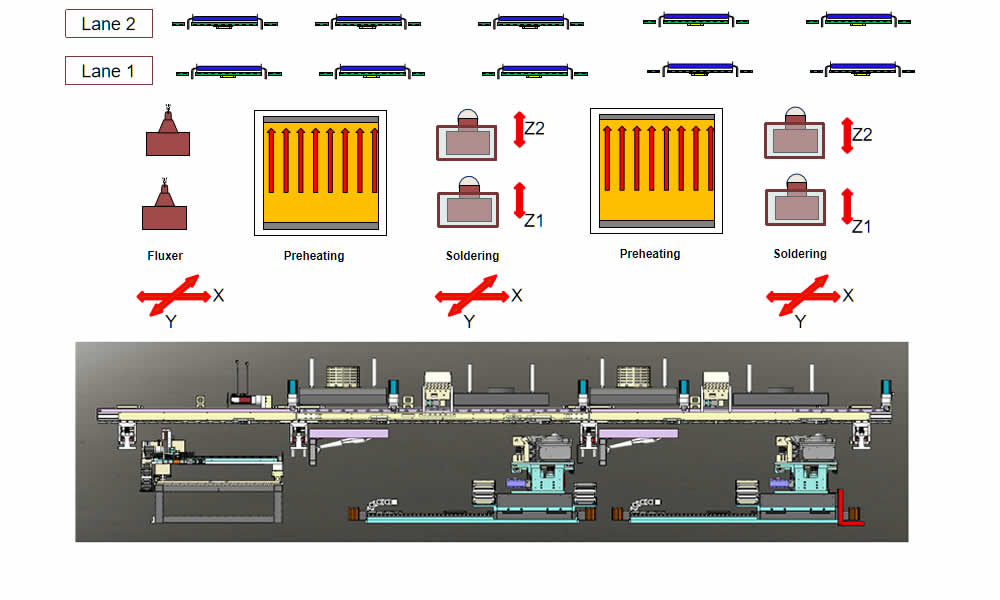

MAS-i22/1 is an inline machine for high output requirements with the following features:

Dual rail conveyor (Max W508 x L508mm)

4 individual solder pots

Can solder for 4 boards at the same time

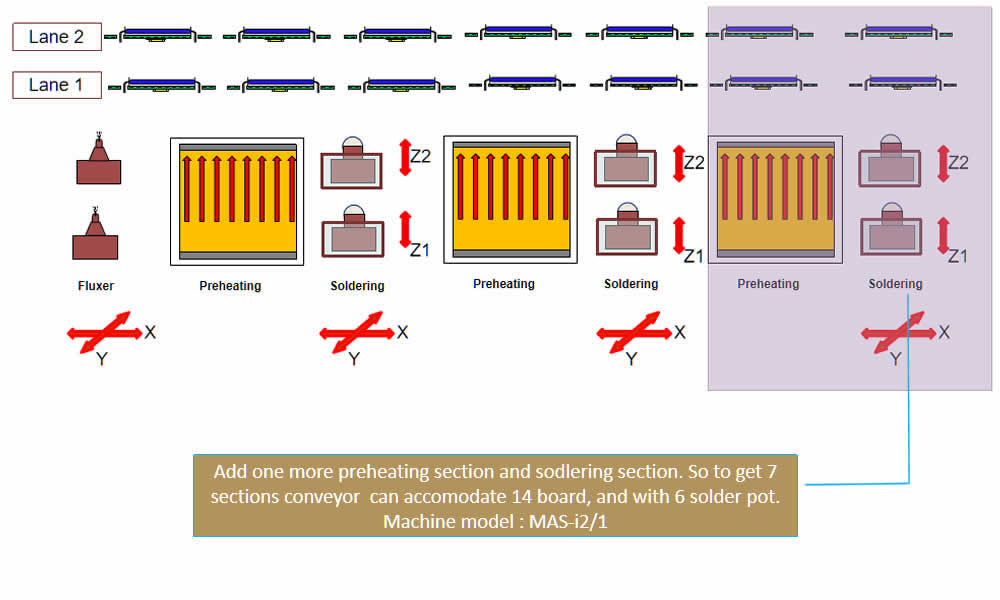

Expandable for 6 pots

Heavy load boards ! Can meet Max 20kg load for each product

High flexibility - use one or both lanes of the conveyor

Max board can size W500mm x L500mm

Windows 10 system

Real-time soldering process monitor

| MAS-i22/1 Specifications | |

|---|---|

| Item | MAS-i22/1 |

| General | |

| Operating power/Max power | 10KW/32KW |

| Machine dimension | 4900(L)*1750(W)*1720(H) |

| Net weight | 2300KG |

| Power supply | 3PH 380V 50HZ |

| Air supply | 3-5 bars |

| Exhausting required | 1300M3/h |

| PC | Yes |

| Typical Program Time | 10 Minutes |

| Conveyor section | |

| Conveyor lane | Single Lane |

| MAX PCB | W508xL508mm |

| PCB top clearance | 120mm |

| PCB bottom clearance | 60mm |

| Max PCB weight | 20kgs |

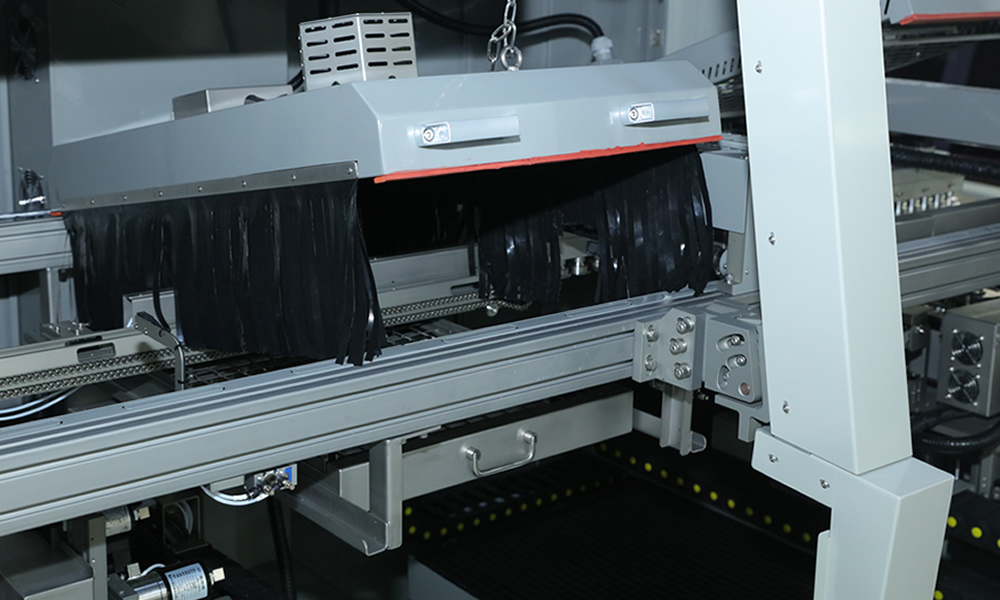

| Selective fluxing table x 1 sets | |

| Flux Nozzle Type | drop jet fluxer made in Germany |

| Flux Nozzle Quantity | Standard equip 1 set |

| Flux Tank Capacity | 1L |

| Flux Tank Quantity | 1pcs |

| Flux Nozzle Distance | width adjustable by software |

| Axes of Motion | X, Y Servo motor |

| Position Accuracy | +/- 0.05mm |

| Preheat section x 2 sets | |

| Preheating method | Top hot air, bottom IR |

| Temperature range | 25--250c degree |

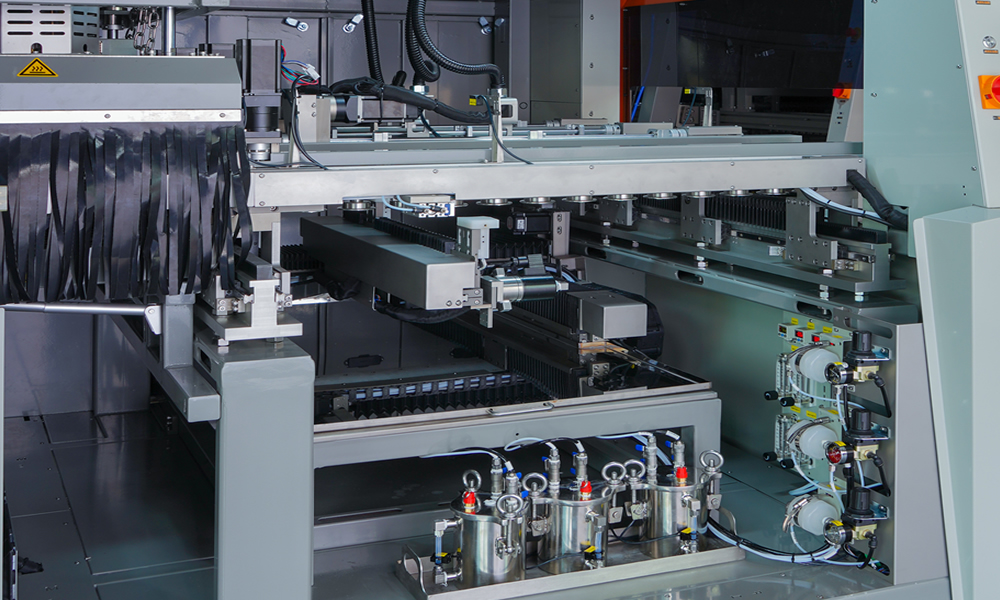

| Selective soldering table x 2 sets | |

| Solder pot type | Standard equipped mechanical pump |

| Solder pot quantity | 1pc/set |

| Solder Pot Capacity | 15kgs/pot |

| Solder level alarm | standard equipped |

| Mini Wave Nozzles | Dia 4,6,8,10,12MM |

| Customized nozzle | Available |

| Motion Control | All servo control with ball screw |

| Position Accuracy | +/- 0.05mm |

| Top preheating | Standard equipped with IR top preheating |

| (N2) Inertion Management | |

| N2 Consumption per Nozzle | 1.5m3/H, total 3m3/H (recommend to use SELMATE-4) |

| Required N2 Purity | >99.99% |